One of the issues I have run into with working from home is the need to be on camera in a room which might be used by others, who would appear in the background. In particular, our office space in the house has a closet behind it which my wife or I would need to use to get clothes or other items, resulting in one of us appearing in the webcam shot of the other.

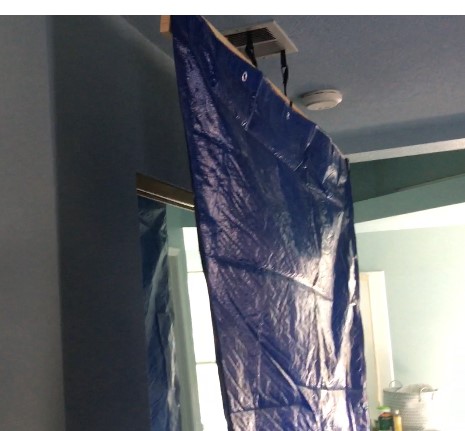

I wanted to come up with a way of adding a screen or backdrop to cover the closet so we could use the closet while the other person is on the webcam and no one would know. The photo below shows what I came up with.

The backdrop is a thick tarp attached to a board via screws. The tarp is then hung up to the ceiling with Velcro strips attached to the board attached to the tarp, which connect to Velcro strips I tied to the heating vent in the ceiling. I love Velcro strips, you can learn more about Velcro strips in my blog post found here. The thick blue tarp I bought I found on Amazon here: Tarp Cover Blue, 2-Pack Heavy Duty Waterproof, Great for Tarpaulin Canopy Tent, Boat, RV Or Pool Cover!!! (8X10, Heavy Duty)

The backdrop works pretty well, below shows how it would look from a webcam perspective with and without the tarp.

I created a video summarizing the steps to create the backdrop and how the backdrop looks which is below: