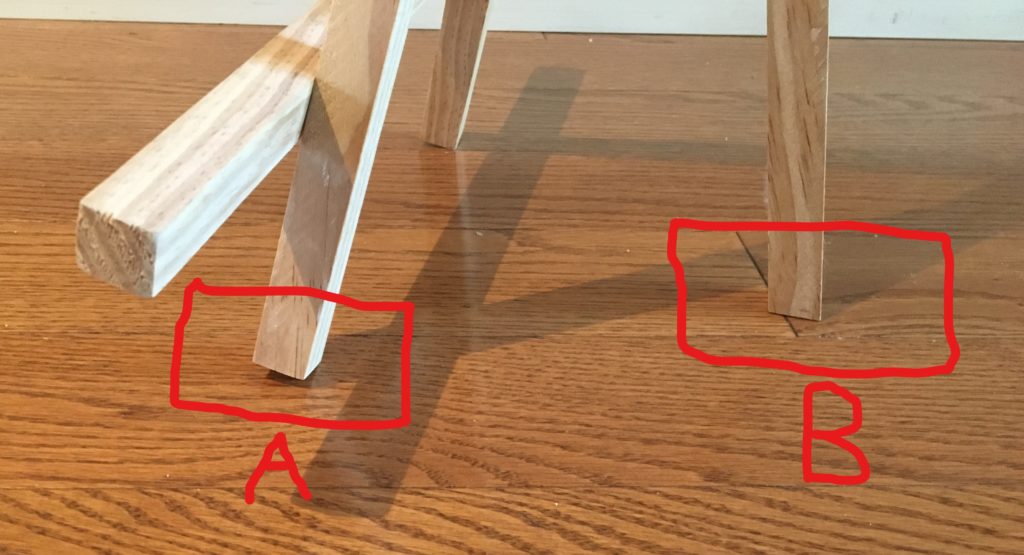

For this project I made a trivet out of pine and oak wood. A trivet is a small plate or board placed under a hot serving dish to protect a table or surface. This is how it turned out:

The process to make the trivet was easy. I cut three pieces of pine wood and two pieces of oak wood, all the same size. Then I glued them together overnight, holding them with three different clamps. After that I sanded it to remove any rough spots. I was going to stain it but my wife told me not do so I did not.

The whole project only took 10-20 minutes of work. It was really easy and I was really happy with how it turned out. See more details in the following video: