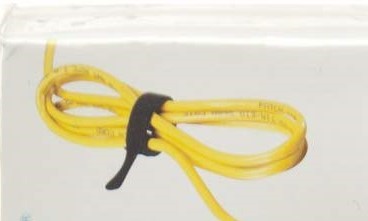

Similar to Velcro strips, zip ties are incredibly useful for attaching things, such as a cable to a wall. However, unlike Velcro strips, the zip tie is permanent or semi-permanent. For example, if you wanted to connect a power cord to a wall I would use a zip tie instead of a Velcro strip since I am unlikely to need to be re-position it anytime soon. Also, note that zip ties are usually cheaper than Velcro strips, with zip ties usually being less than a penny each. They come in varies sizes and colors as shown in the picture below.

Here is a link to assorted zip ties on Amazon, where you will find they are pretty inexpensive:

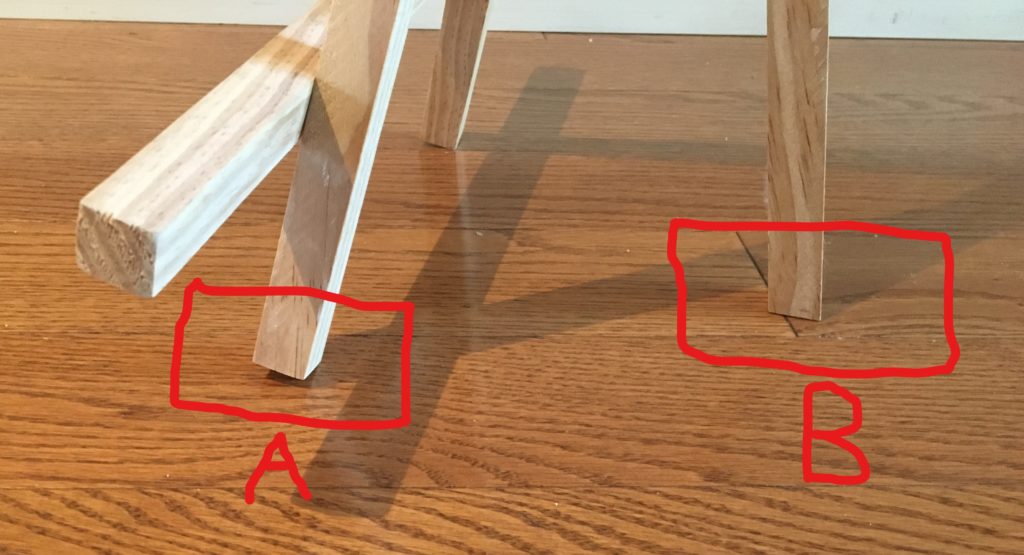

Here is an example of using a zip tie in your house, I zip tied protective foam to my indoor trampoline to protect my walls from being scuffed.

Also I hung up my pickle ball racket by making a loop with a zip tie and threading that through the zipper as shown in the photo below.

In general, zip ties can be used for a lot of things around your house and they are cheap and disposable. I would recommend everyone get some for various uses around their house.

I discuss the uses of zip ties a little further in this video.